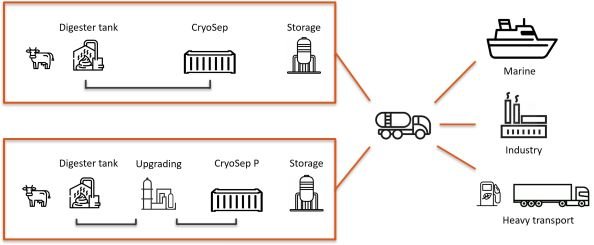

This is how we produce liquid biogas

Biofrigas' CryoSep family are container-based facilities that enable smaller producers such as agricultural, municipal facilities and food industries to produce liquid biogas from their organic waste streams. As a starting point, CryoSep uses the gas produced in a digester, so-called biogas, which consists mainly of methane and carbon dioxide. In cases where the biogas after the digester has been upgraded to biomethane, in an upgrading facility, CryoSep P is used.

The main processes for both CryoSep and CryoSep P are essentially the same. In the first step of the process, the gas is cleaned of impurities such as hydrogen sulphides, particles and water in order to separate methane and carbon dioxide in two different flows in the next step. The methane separated has a very high purity, which enables the third and final step, liquefaction. In the liquefaction step, the methane gas is cooled to -160°C and then converted to liquid, which creates the end product liquid biogas, also called LBG (Liquid biogas) and consists, in principle, of pure methane. The liquefied biogas is then stored in storage tanks in connection with the production plant and it is from these tanks that the liquefied gas is collected by trucks that transport the gas to the customers.

CryoSep is based on the gas, often called biogas, that comes from the natural digestion process that breaks down organic and biological waste in different types of digestion chambers. The biogas typically contains 55-65% methane and 35-45% carbon dioxide. CryoSep P is based on upgraded gas, which typically contains 97-98% methane and 2-3% carbon dioxide. See the sketch below for a schematic view of the various components. For a more detailed description, please contact us fo a copy of our technical description.

The main performance of the various plants is shown in the table below.

| |

CryoSep |

CryoSep P |

| Process |

Upgrading & liquefaction |

Polishing & liquefaction |

| Capacity - Incoming gas |

35 Nm3/h (Biogas) |

120 Nm3/h (Biomethane) |

| Typical methane content - incoming |

65% |

98% |

| Liquid biogas - Out |

145 tpa / 2 GWh |

735 tpa / 10 GWh |

| Liquid CO2 - Out |

210 tpa |

40 tpa |

A main product with several by-products

In addition to the main product, liquid biogas, the process also creates liquid biogenic carbon dioxide, a product with many uses where it can replace carbon dioxide of fossil origin. Applications can be in the food industry, for greenhouses or as an input material in, for example, cement production. Other areas of use can be as welding gases, CO2-ice or for fire extinguishers.

As part of the digesting process, an excellent bio-fertilizer is also obtained.

Our technology unlocks new potential

Our proprietary technology opens two doors at the same time. In part, the container-based plant makes small-scale production of biogas realistic. Currently, almost all production takes place at a few large-scale facilities, but it is in the locally produced and small-scale that much of the future potential lies. CryoSep fits in a 40-foot container, which means that the technology comes close to the businesses where there is biodegradable waste to dispose of. In this way, an important resource is taken care of, which previously was not financially sustainable to extract.